HIGH VELOCITY OXYGEN FUEL (HVOF)

HVOF Coating Services

Powered Coating That Packs A Punch

The ultimate wear-resistant coating, HVOF delivers a premium finish.

Our High Velocity Oxygen Fuel (HVOF) offers a dense, low porosity coating that provides better wear resistance, increased hardness, higher bond strengths, and more protection than other coating solutions. In fact, our premium HVOF coatings can produce deposits with less than 1% porosity.

GOOD TO KNOW

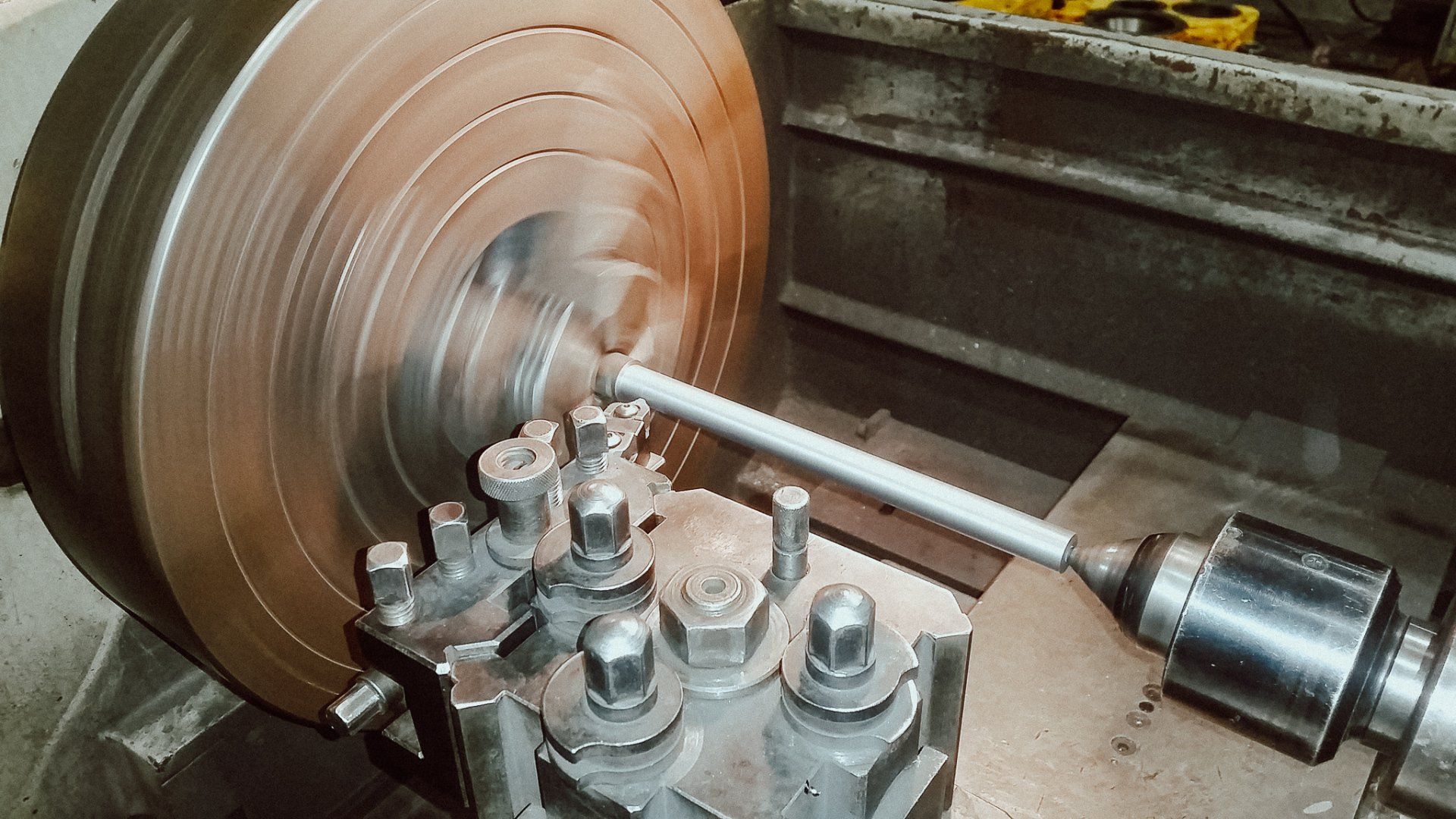

At New Metal Surfaces, HVOF coatings services are completed using advanced automated machinery (6-axis KUKA robot on a 7th axis linear track, if you want to get technical). This allows for smooth, even coating to all components — every time. It also means we complete projects quickly, without sacrificing a premium finish, and get your components back to you sooner.

Quick turnarounds

Smooth & even coating

High performance coating

Applications

- Provide superior rebuild and salvage operations.

- Increase abrasion resistance.

- Increase sliding wear resistance.

- Increase resistance to fretting, galling or adhesive wear.

- Increase resistance to cavitation effects.

- Increase resistance to chemical attack.

- Increase control of oxidation and sulfidation.

- Increase atmospheric and high temperature corrosion control.

Components

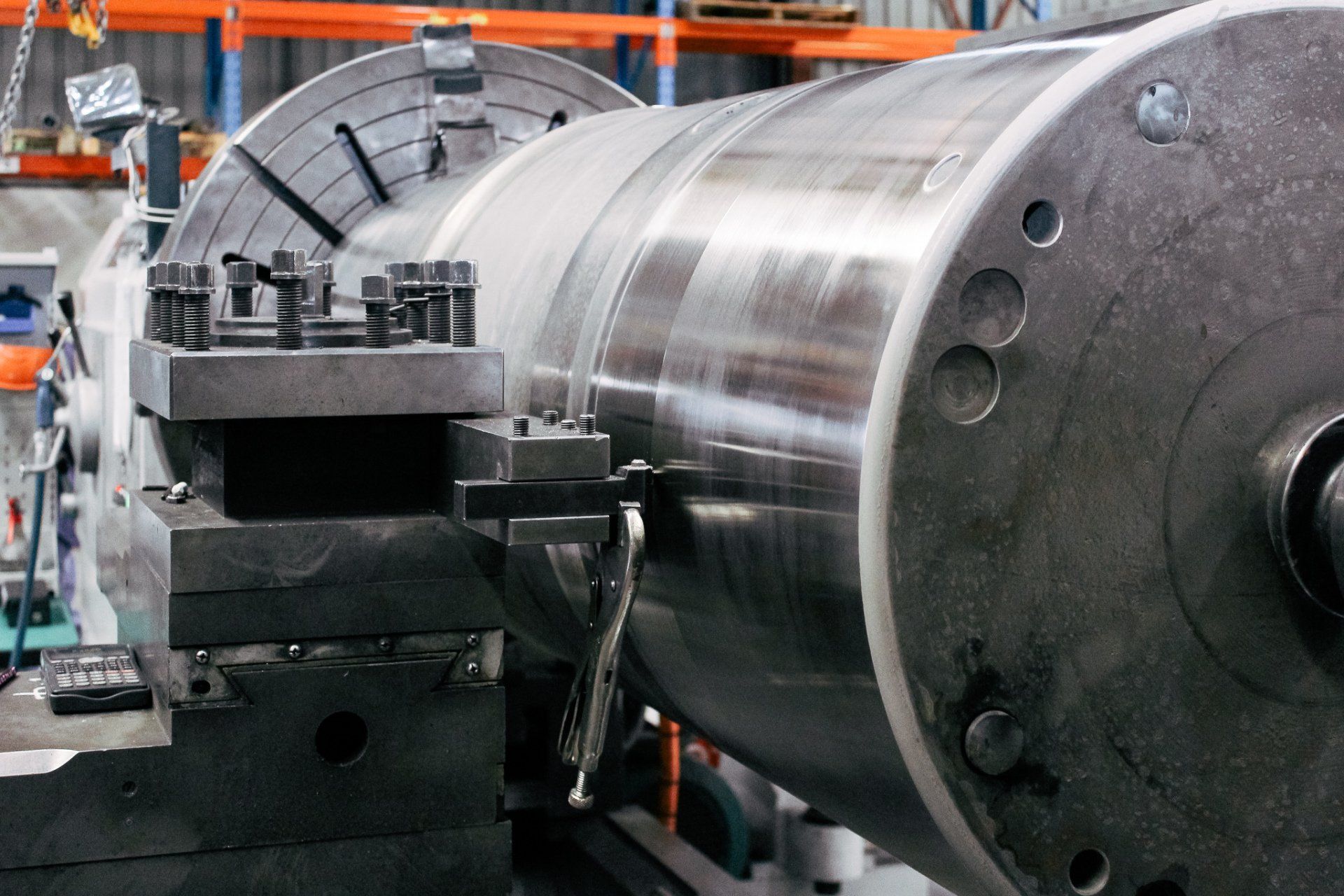

- Rotors.

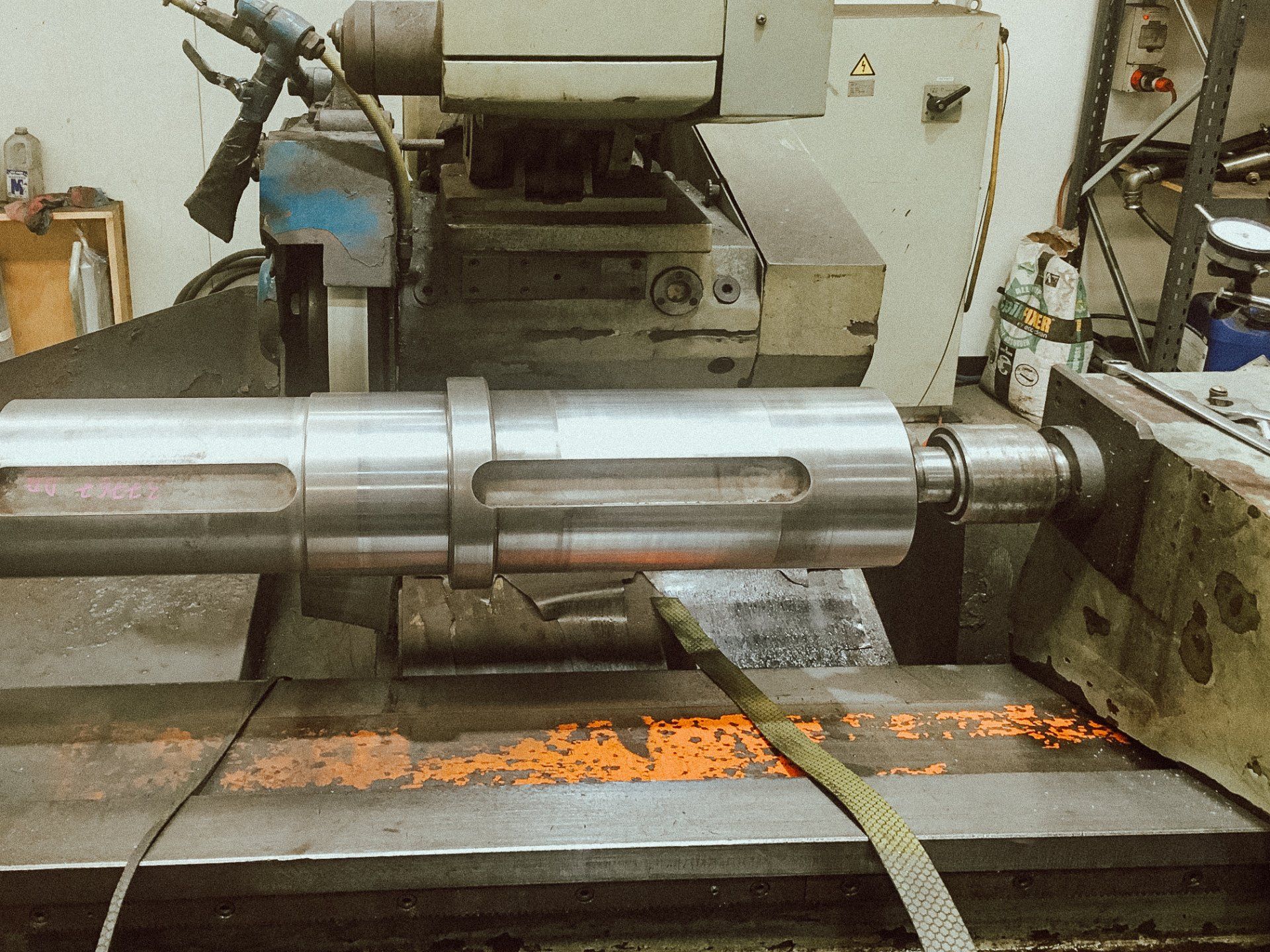

- All kinds of shafts, including drill shafts, gear shafts, main shafts, pulley shafts, input and output shafts, as well as drive shafts.

- Rods.

- Spindles.

Tech talk

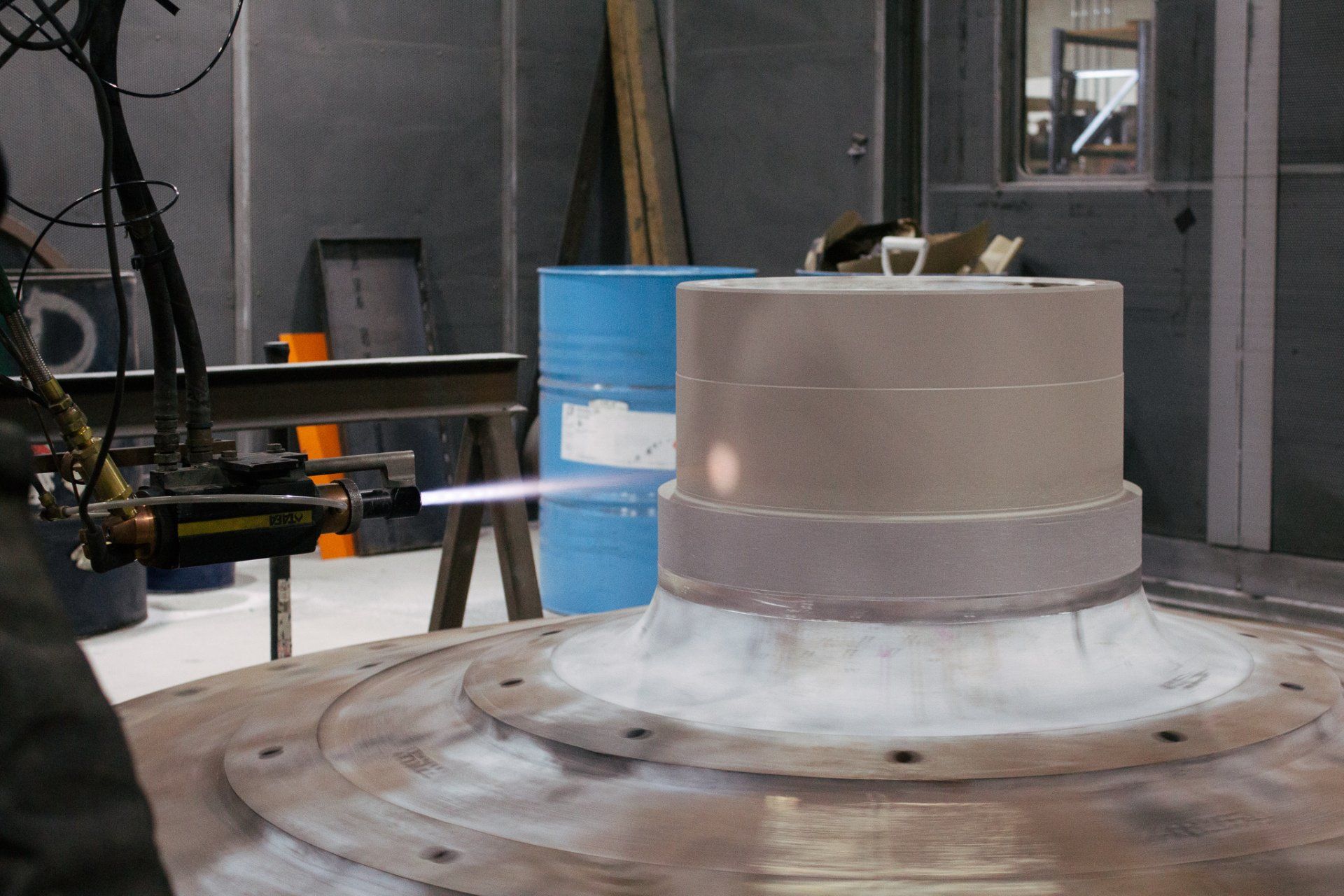

Using our 6-axis KUKA robot on a 7th axis linear track, we apply HVOF coatings by mixing fuel and oxygen, which is fed into a combustion chamber and ignited.

The generated gas has an extremely high temperature and pressure, which is ejected through a nozzle at high speeds. Next, powder is injected to the gas stream, and that powder partially melts. Lastly, the stream of gas and powder is directed towards the surface to be coated.