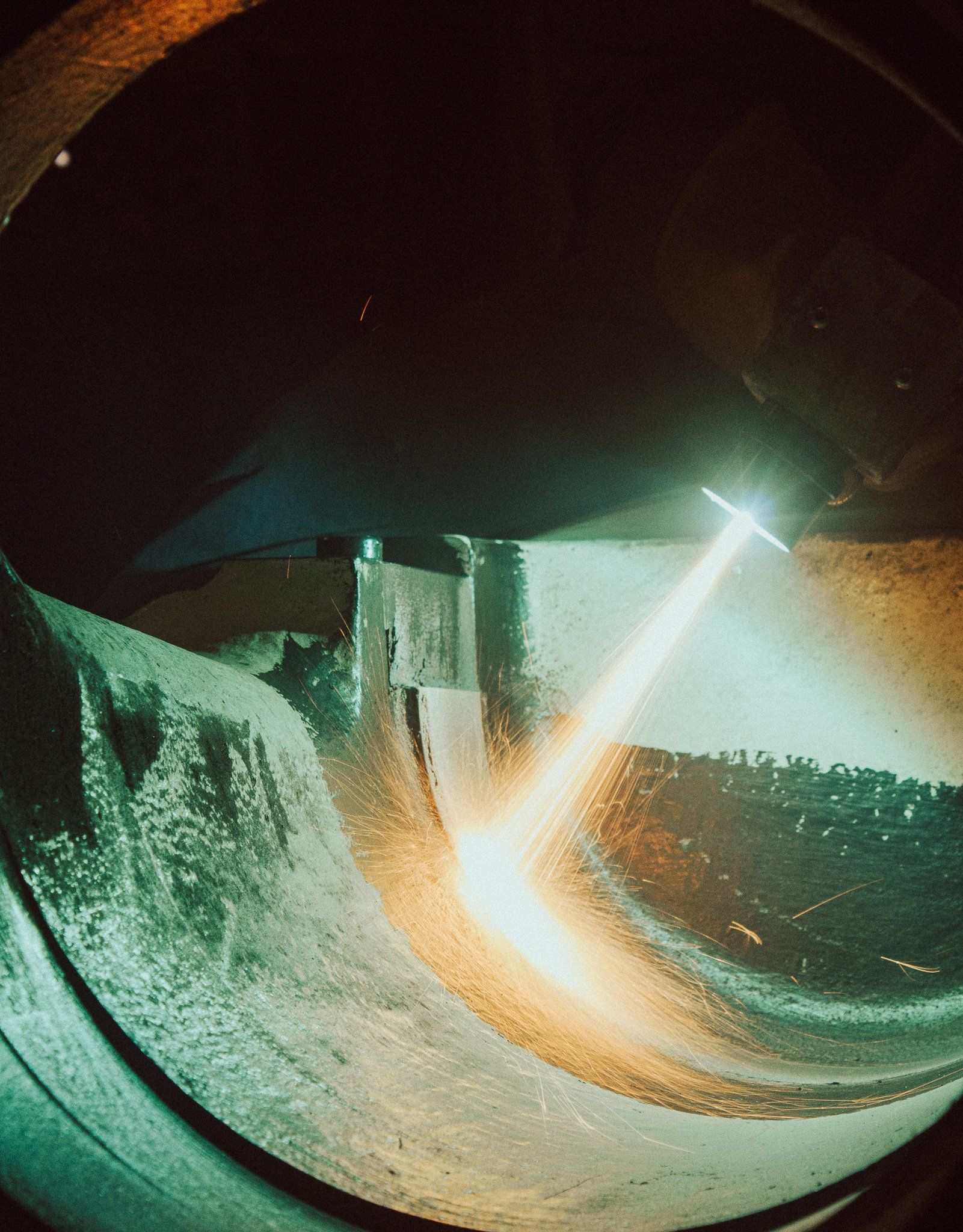

ARC SPRAY

A quality all-purpose coating solution.

Arc Spray, or Twin Wire Arc Spray, is our best thermal spray solution for all-purpose coating, as it can be applied in a range of situations.

GOOD TO KNOW

All our Arc Spray coatings are carried out in our purpose-built acoustic reduction booths, using 6-axis KUKA robots. This ensures we provide our customers with the best quality coating, whilst keeping our team as safe as possible.

Quick turnarounds

Smooth & even coating

High performance coating

Tech talk

Twin Wire Arc Spray utilises two metallic wires (one positive and one negative) fed into a torch at matched speeds.

When these opposing wires meet at the torch head, they create an electric arc that melts the wire ends. Compressed air is then used to atomise and accelerate these particles onto the work surface.

A material for every need

At New Metal Surfaces, we have a wide variety of different metal coating materials available, all offering a coating with high bond strengths, high deposition rates, and minimal substrate heating.

Applications

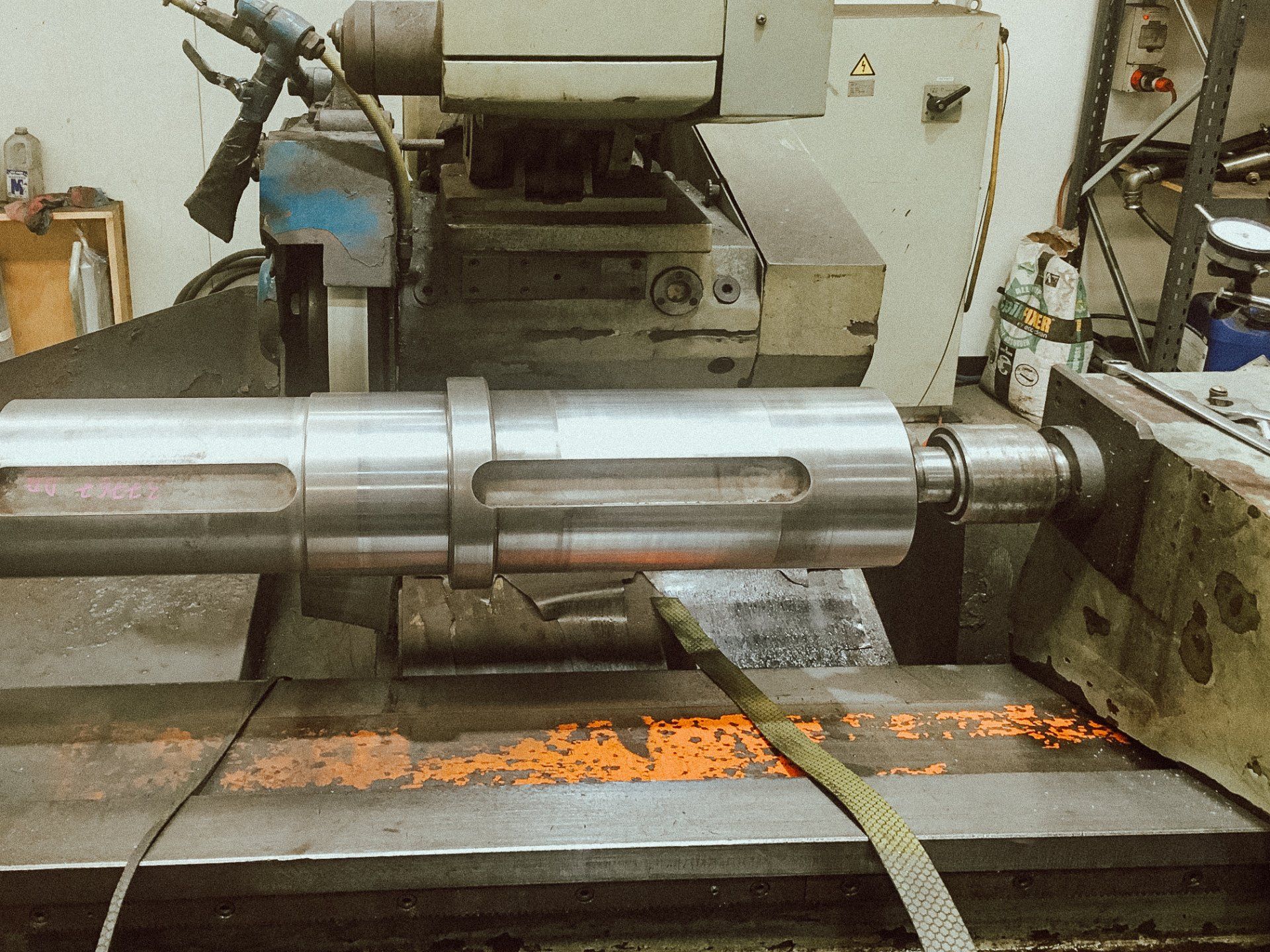

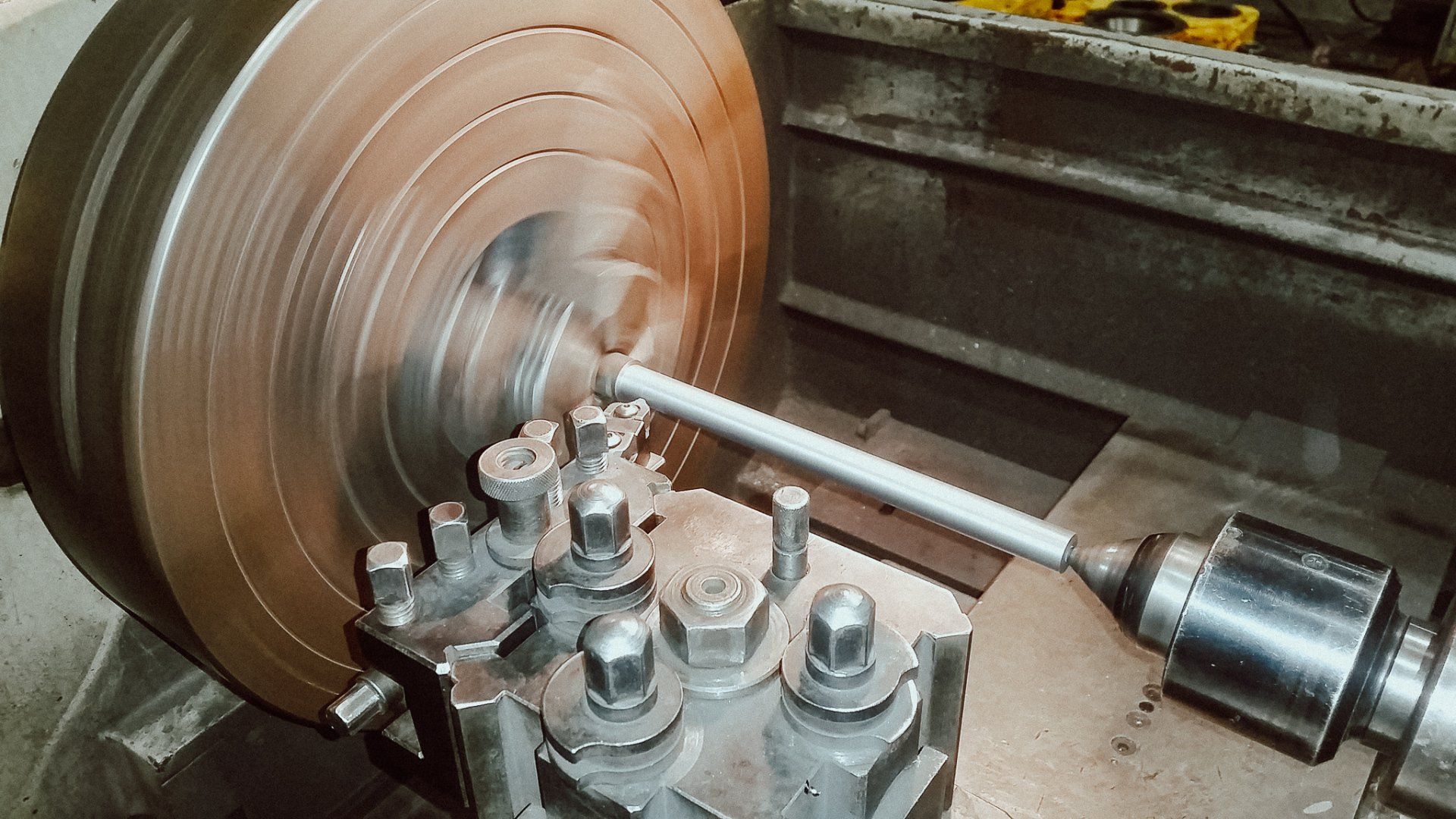

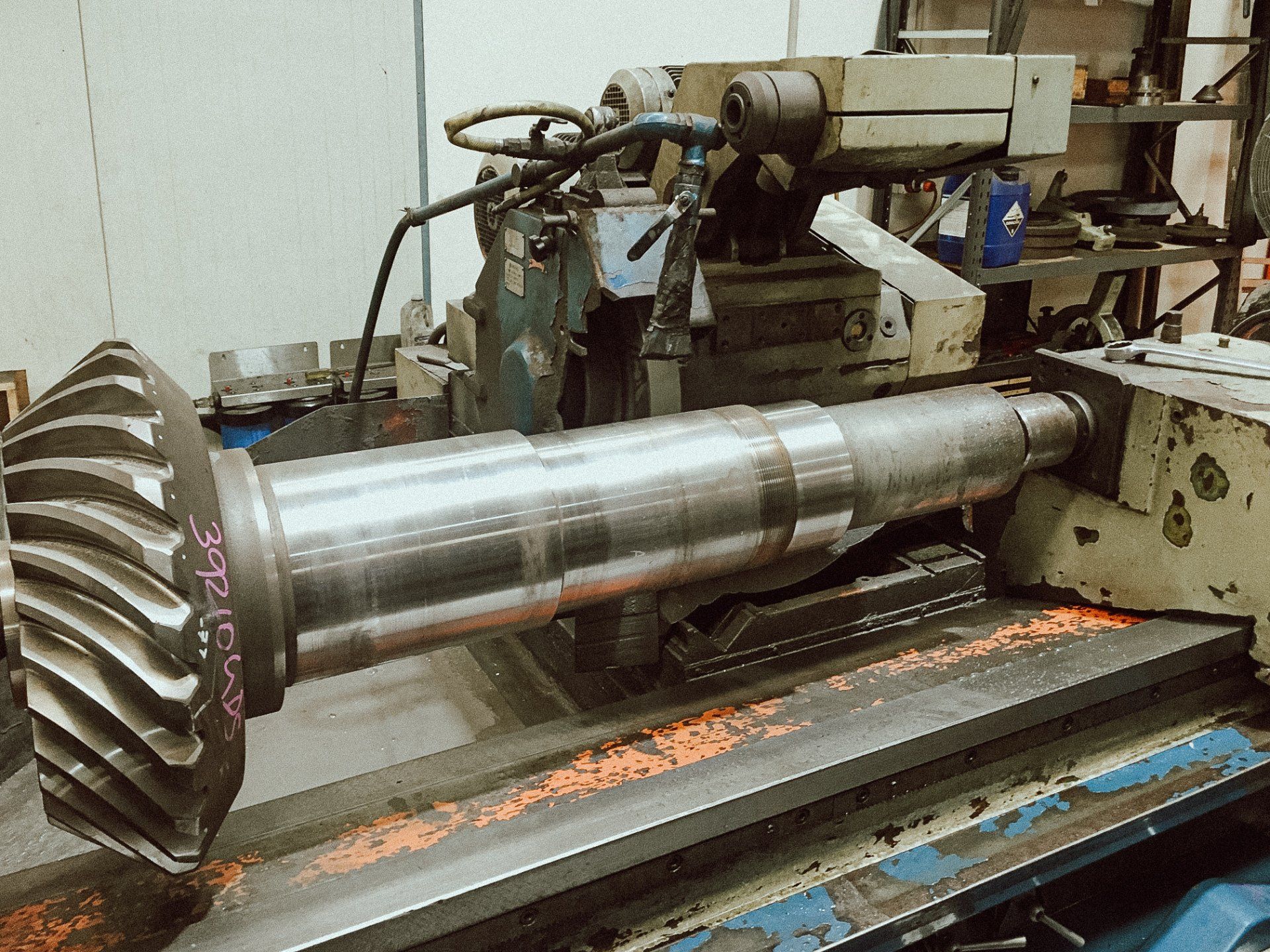

- Reclaim worn, damaged, or mis-machined parts

- Increase atmospheric and high temperature corrosion control

- Rebuild and salvage components

- Provide electrical conductivity

- Provide anti-skid and traction coatings

Components

- Gearbox Housings

- Diff Carriers

- Front & Rear Wheel Hubs

- Brake Housings

- Covers

- Flanges

- Yokes

- Spindles

- And more