RCR Mining Technologies - Mill Trunnion Repair

RCR Mining Technologies has been a valued customer of New Metal Surfaces for many years. Over the past couple of years, they have continually trusted our team to deliver high quality work to restore their worn and damaged components.

THE PROBLEM

RCR Mining Technologies engaged our team to devise a repair solution for a damaged mill trunnion from one of their clients’ sites. We worked with RCR in June to provide a solution that would allow them to get their clients mill up and running again, whilst they waited on a new mill trunnion, that due to long lead times would not be ready until 2023

THE SOLUTION

1. Our team began by visiting RCR Mining and inspecting the damaged area in person to provide a recommendation for the best repair procedure given the substrate material and what application the component would be used.

2. Once the client approved our repair, we began by prepping the trunnion for spraying. During this process, we welcomed representatives from RCR to inspect the component and be present for the MPI crack testing. This allowed us to understand exactly the needs of our client and provide assurances of the quality of work that they will receive.

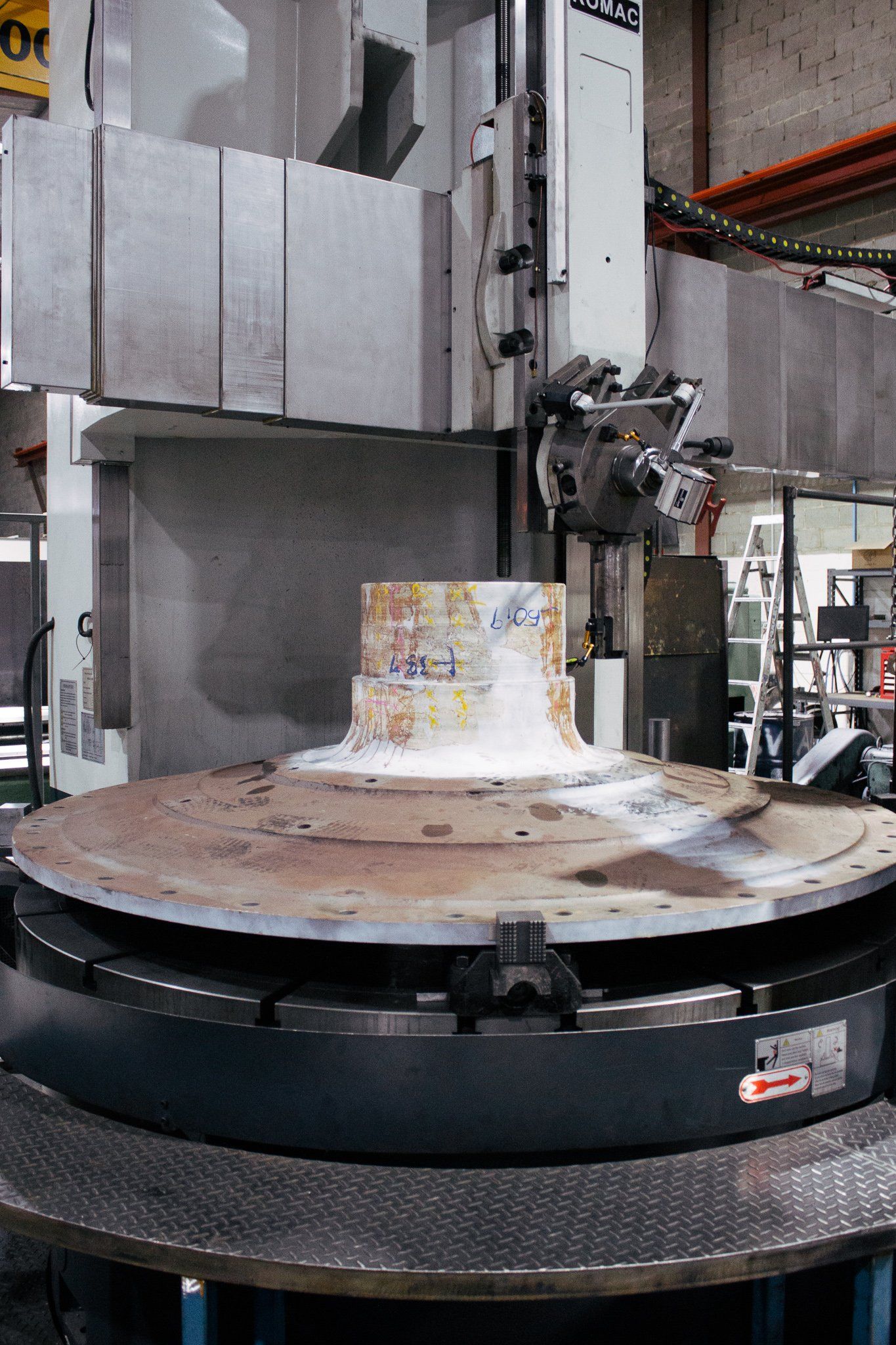

BEFORE

DURING PREP MACHINING

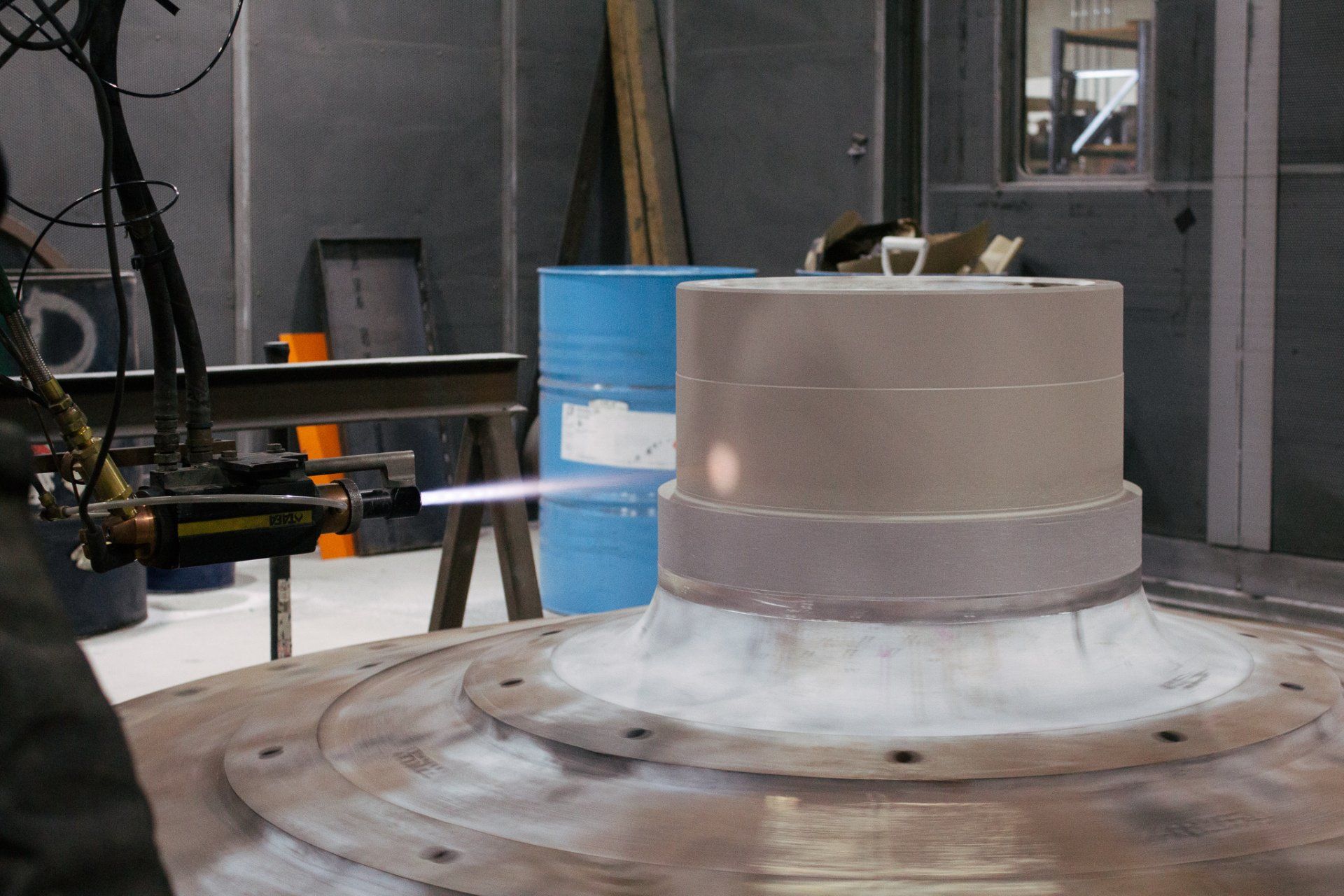

4. After spraying the damaged area, the mill trunnion was placed back on our Vertical Borer to be finish machined to its final dimensions.

5. The finished result was a restored mill trunnion that was finished on time and installed on site by RCR in early July that will ensure the end client is able to get their mill back up and running.

DURING SPRAYING

CUSTOMER TESTIMONIAL

“The service provided by New Metal Surfaces was next level. From quoting to the follow ups visits at the workshop and the interactions with their machinists during MPI checks. The metal spray solution provided our client with the ability to get their mill back up and running while they wait for a new mill trunnion in 2023 due to long lead times.

RCR appreciated the professional and friendly service provide by New Metal Surfaces and look forward to working together on future projects.” — Vince, OSR Manager.

AFTER