A Brief Glossary: HVOF Thermal Spray Coating

Throughout our website, we use terminology you may not be familiar with to describe some of the services we provide. Where this is unavoidable, we hope that you’ll still be able to get to know us and what we do.

Below we’ve put together a brief list of definitions that may help to guide you through one of our primary services: HVOF thermal spray coating.

SIGN UP

Enter your email to sign up to our newsletter!

Contact Us

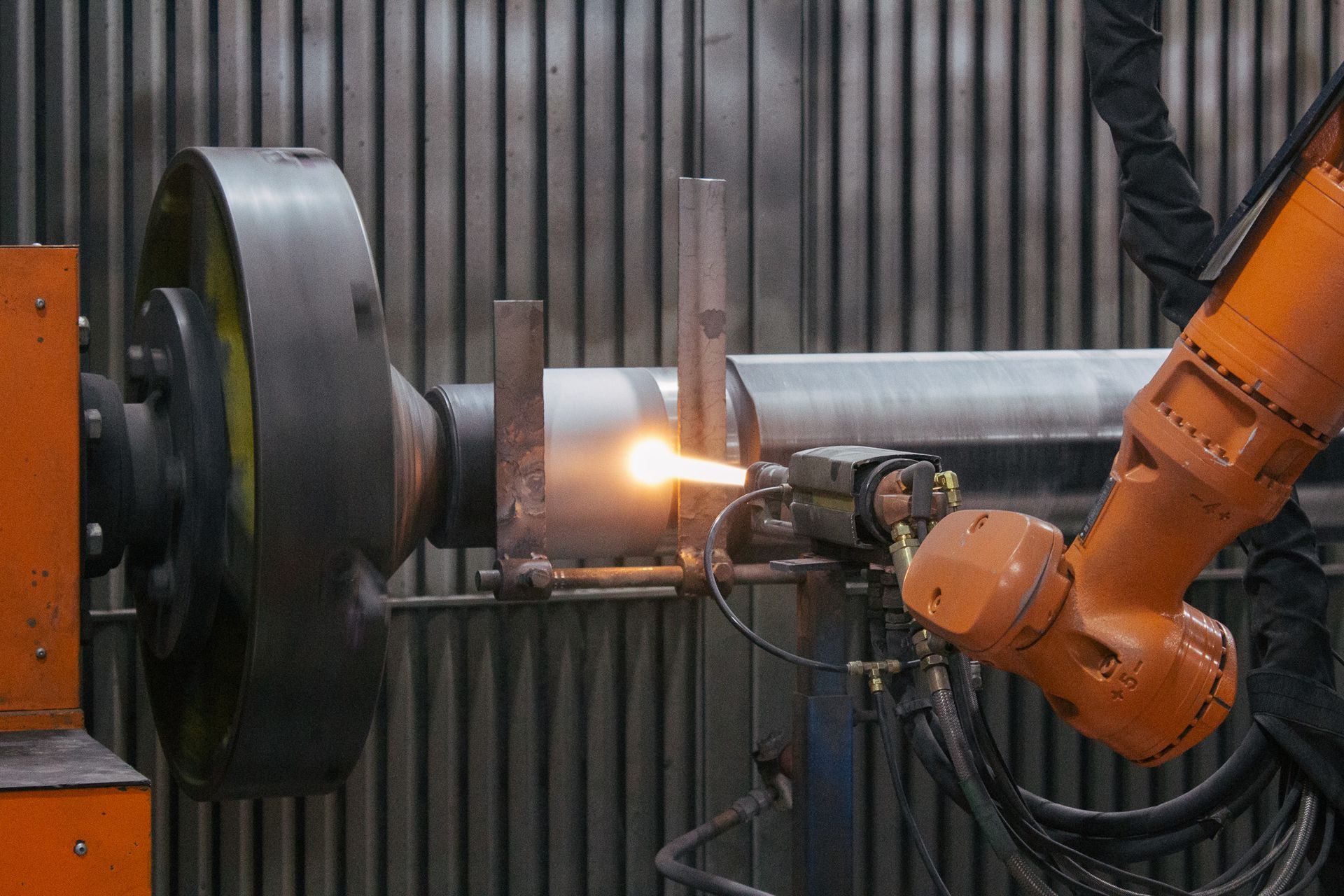

HVOF Thermal Spray Coating:

A process that involves accelerating small particles of heated metal onto a surface using a high-velocity stream of gas. This creates a durable, protective coating that can be used to enhance the performance and lifespan of industrial components.

High-Velocity Oxygen-Fuel (HVOF):

A specific thermal spray coating process that uses a high-velocity stream of gas (typically oxygen or a mixture of oxygen and fuel) to spray a heated material onto a surface.

Low Porosity:

Porosity is the degree and amount of ‘holes’ within a coating through which environmental material can enter and damage the substrate. HVOF offers a low level of porosity in its coatings due to the high impact velocities that are achieved by the in-flight particles. This makes them less susceptible to corrosion and other types of damage.

Coating Adhesion or Bond Strength:

How well the sprayed material and the surface mechanically interlock and ‘stick’ together. This is typically measured by the force required to separate the coating from the surface. Good adhesion or bonding is essential for a durable, long-lasting coating.

Corrosion Resistance:

The ability of a material to resist degradation caused by (chemical reactions with) its environment, such as exposure to moisture or corrosive chemicals. Corrosion resistance is important for preventing the wear and failure of industrial components.

Wear Resistance:

The ability of a material to resist damage or erosion caused by mechanical forces, such as friction or impact. Wear resistance is important for protecting critical components from damage and extending their lifespan.

WE’RE READY

Contact us to learn more about our HVOF thermal spray coating process or to see if we can help with your coating needs.