HVOF Thermal Spray Coating FAQ

Is HVOF thermal spray coating right for you?

At New Metal Surfaces, we specialise in the application of thermal spray coating solutions. Our family-owned business has been using HVOF thermal spray coating to repair components across a range of industries since 2011. It’s a process we firmly believe in and a service we’re proud to deliver.

Learn a little more about the HVOF thermal spray coating process with a few of our most frequently asked questions answered below.

SIGN UP

Enter your email to sign up to our newsletter!

Contact Us

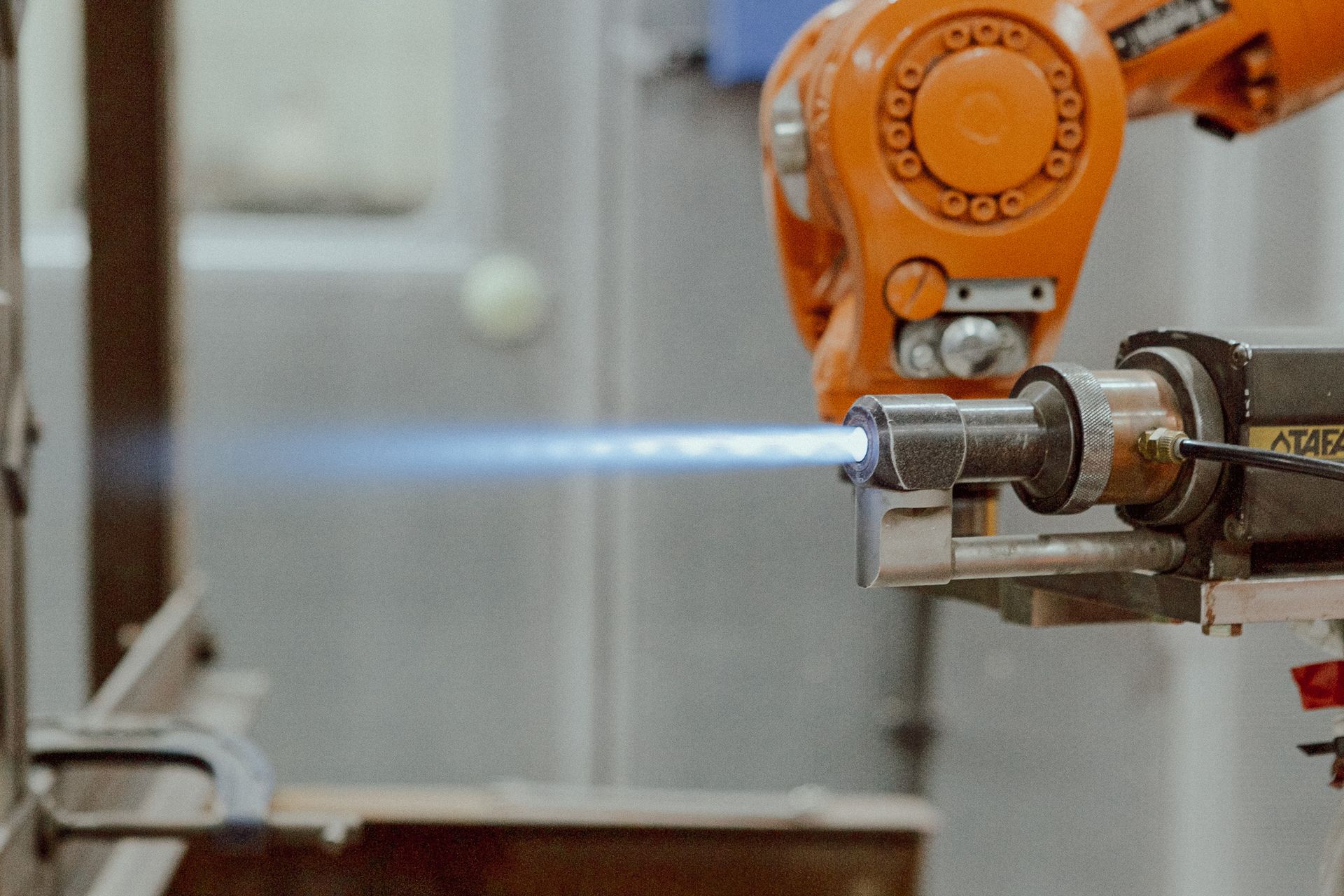

What is HVOF thermal spray coating?

HVOF thermal spray coating is a process that involves accelerating small particles of heated metal onto a surface using a high-velocity stream of gas. This creates a durable, protective coating of industrial components to enhance their performance and lifespan.

What are the benefits of HVOF thermal spray coating?

HVOF thermal spray coatings can be used to improve wear and corrosion resistance, thermal insulation, adhesion and surface finish. They can also be applied to a variety of materials and surfaces, making them a versatile solution for a range of industries.

What industries use HVOF thermal spray coating?

HVOF thermal spray coating is used in a variety of industries, including industrial pumps, drilling, material handling, earth moving, oil and gas, aerospace, and power generation. Any industry that requires durable, high-performance components can benefit from HVOF coatings.

What materials can be used for HVOF thermal spray coating?

A wide range of materials can be used for HVOF thermal spray coating. We can spray a variety of cermets such as tungsten carbides in metallic binders and metal alloys. The material used will depend on the component being coated, its application and its required properties.

How is the HVOF thermal spray coating applied?

HVOF thermal spray coating is typically applied by injecting an oxygen-kerosene mixture into a combustion chamber within the spray gun which is then ignited. Powdered material is injected, and the high-velocity stream of gas partially melts and propels it onto the desired surface. This process is controlled to achieve a specific thickness and uniformity.

How does HVOF thermal spray coating compare to other types of coating?

HVOF thermal spray coating is known for its superior wear resistance and corrosion resistance compared to other types of coating, such as laser cladding and hard chroming. It can also be applied to a wider range of materials and surfaces than other coating methods. Want a more detailed look at how thermal spraying and laser cladding compare, Check out this blog.

Can HVOF thermal spray coating be used to repair damaged components?

Yes, HVOF thermal spray coating is commonly used to repair components that have been damaged by wear or corrosion. The damaged area is prepared and then coated with the appropriate material to restore the component to its original condition.

How long does HVOF thermal spray coating last?

The lifespan of an HVOF thermal spray coating will depend on a variety of factors, including the material used, the application, and the conditions in which the component is used. Generally, HVOF coatings are known for their durability and long lifespan compared to other types of coating.

WE’RE READY

Contact us to learn more about our HVOF thermal spray coating process or to see if we can help with your coating needs.